At the end of my last call, I put down my headphones and smiled. It just happened again. …along with multiple times this week. What was it? I heard business buyers string together a set of “belief statements.” These are commonly held as “truths” in the industry. The interesting thing for me is how false these “truths” are. The closer you get to the heart of the beast of software buying, the more you understand; and the quicker you realize them as falsehood(s). Here I attack the five myths I see the most often.

Before I start, let me share my bias. I am an industry analyst. I triangulate the market and rate software. I do not implement. I write for the early adopter business leader. In this role, I work with business teams as an adviser to build digital transformation strategies or drive improvements in supply chain excellence. My focus is quite different than that of a consultant.

Here are the five myths that I see the most often:

Claudio Muruzabal, president of Latin Americas & Caribbean for SAP SE, listens during the Americas Society and Council of the America annual conference in Buenos Aires, Argentina, on Thursday, Aug. 24, 2017. The conference brings together key government officials, legislators, and private sector leaders to address Argentina’s economic outlook, as well as the country’s political prospects leading up to the October legislative elections. Photographer: Pablo E. Piovano/Bloomberg

1. Consultants Are An Independent Source of the Truth. On the call today, there were four business leaders and three consultants. The consultants were recommending a software solution. In the discussion, there was no disclosure that the consultants get a percentage of the sale. By definition, they are a distribution arm for the technology provider. Tightly tied at the hip of the software provider leads to weird dynamics. For example, when I questioned the client on the consultant’s recommendation, the consultant promptly called the software provider, and I quickly got a call from the CEO of the technology company. This happened despite the fact that both the consultant and I have NDAs (non-disclosure agreements)with the manufacturing client. Make no doubt about it. Consultants recommend the software that enables the most profit for the firm. As a result, the recommendation is usually an expensive solution requiring many hours of implementation. Consultants are not independent.

2. Software From the Same Technology Provider Will be Easier to Implement. Integration Will Be Easier. This is a commonly-held belief. The sad thing is that it is not true. For example, the recently introduced solution SAP Integrated Business Planning (IBP) is tougher to integrate to SAP ERP than alternatives. Yet, because the same suite is sold by SAP, there is a belief that integration will be easier. This week, I helped to arbitrate a polarized discussion within a manufacturing company. The Information Technology (IT) group was fighting for IT standardization. There was a 3X impact on cost and a substantial difference in business fit; but at the end of the day, the IT team won. As a result, the company got a solution that will be harder to implement, more costly and a poorer business fit. Software vendors perpetuate the myth that since the solution is sourced from a single vendor that integration will be easier. Most of the time, this is just not true leading companies to pick a more expensive solution, that may not fit their needs.

3. Digital Innovation in Packaged Software for Supply Chain Exists Today. There is no one definition of a digital transformation; however, there are many promising innovation triggers. The convergence of new technologies–mobility, ecommerce, Internet of Things, 3D printing, machine learning, robotics, cognitive computing–redefine processes and open the door to new business opportunities. Best-of-breed technology providers are driving innovation faster than the most established solutions. As a result, investments in traditional supply chain technologies like Enterprise Resource Planning (ERP) and Advanced Planning (APS) are an opportunity cost to making the digital pivot. Companies that are the most interested in driving digital transformation should be stabilize traditional investments. These traditional software packages are not the backbone of digital transformation.

4. Consultants Can Successfully Build and Sell Software. The business models for software and consulting are distinctly different. While software focuses on systemic platform evolution and upgrades, the consulting model is focused on one-off implementations. Consultants focus on short-term and urgent client requests while software providers focus on long-term software evolution. As a result, the evolution of software under consulting leadership is a poor track record. It is for this reason that I recommend that clients never buy software from a consultant.

5. Innovation Strategies Can Be Implemented Using the Project Plans and Assumptions of the Past Decade. In the implementation of software over the last ten years, there were assumptions. The first was that companies were implementing best practices, and that with a successful definition of the “to be” state that the company easily move forward with a project plan to transform processes from the “as is” to the “to be” state. The project plan was well-defined with key milestones and a Return on Investment (ROI). In contrast, this new world of innovation, there is no well-defined ROI. The implementations require testing, refinement and evolution. As a result, the projects need different implementation methodologies and expectation.

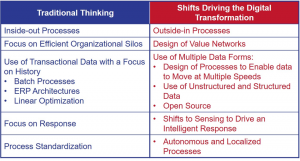

To get started on the evolution of digital innovation, teams must question existing processes. For supply chain leaders, I contrast these differences in Figure 1. The groups must learn, to unlearn to relearn. The unlearning is the hardest part.

Figure 1. The Contrast of Process Shifts

Comparison of Traditional Supply Chain Processes to Emerging Digital InnovationSupply Chain Insights

New processes move at the speed of business. Traditional processes do not. In addition, they cannot sense. They respond. Digital transformation is based on outside-in processes that sense, learn and act. In contrast, traditional processes are inside-out batch-based processes using latent transactional data.

When I work with clients, to make the point of how stark of a change this is, I ask teams to think back to their lives before the evolution of the mobile phone, streaming media, and personal computers. I then ask them to list the ways that technology changed their personal lives. Then, to show the contrast, I ask for them to do the same comparison of their business processes. In the process of this activity, they quickly realize that their personal lives underwent massive transformation, but that their enterprise processes have changed little since the 1990’s. Unanimously, they will agree that it is time to push on. My point of view is that this cannot happen unless they bust the current myths of software/consulting sales cycles and understand that most of the software currently deployed in supply chains is legacy. By definition, traditional software approaches are note the foundation for the digital transformation.

I’m founder of Supply Chain Insights LLC and the author of popular enterprise software blog Supply Chain Shaman. My book, “Bricks Matter,” now on the second printing, published in December, 2012. I am now writing my second book about industry performance on driving supply ch…

Lora Cecere is a supply chain visionary. In 2012 she founded a company, Supply Chain Insights, to understand supply chain excellence. She actively writes weekly posts on the Supply Chain Shaman blog.

Author – Lora Cecere, Contributor

Courtesy of https://www.forbes.com/sites/loracecere/2017/10/27/debunking-five-myths-for-the-business-buyer-of-enterprise-software/#3ee1fe511d1d